Warradarge Green Hydrogen Project

warradarge green hydrogen project

Powered by onshore wind and solar, the Warradarge Green Hydrogen project will generate green hydrogen, a versatile renewable energy resource designed to tackle hard-to-abate sectors of the carbon economy, reduce global reliance on fossil fuels, cut greenhouse gas emissions, and slow the pace of global warming.

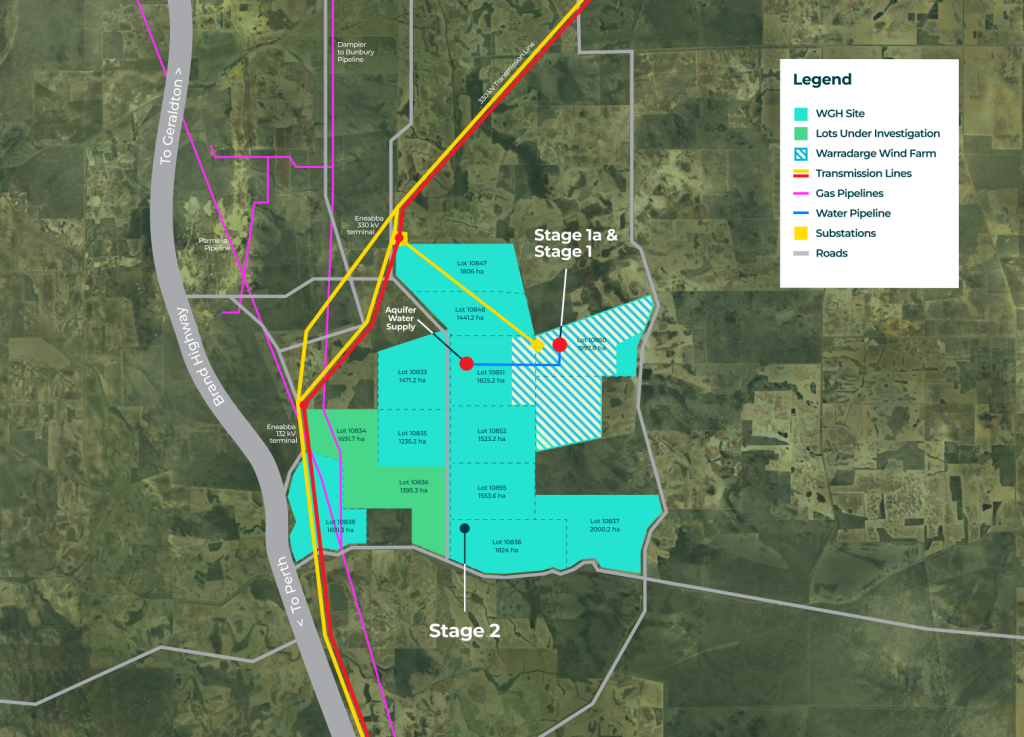

The project will be delivered across two stages, with Stage 1a/1 delivering a renewable fuel as a diesel substitute for heavy haulage, and Stage 2 targeting industrial applications.

Stage 1a and 1 are located adjacent to the Warradarge Wind Farm, about 20km south of Eneabba, this site is renowned for its diurnal wind and solar conditions, making it ideal for green hydrogen production.

Stage 2, located 10km to the south, will be developed alongside a new wind farm and solar farm.

The Project will draw groundwater from the Yarragadee Aquifer as the feedstock for the electrolysis plants.

Stage 1a & 1 Project Objectives

Green Hydrogen Production: Utilise renewable energy from a behind the meter connection to Warradarge Wind Farm to produce hydrogen through electrolysis – splitting water sourced and purified onsite from the Yarragadee aquifer. Stage 1a commences with the initial installation of 26MW of electrolysis capacity, scaling up to 196MW to complete Stage 1 and meet customer demand.

Storage & Compression: Hydrogen gas is then compressed and stored onsite ready for transport via tube trailers

Distribution: Efficient and on-time deliveries to our customers at common user refuelling sites along existing high volume transport sites, initially focusing on the Geraldton area.

Economic & Environmental Benefits: Provide tangible financial value and cost certainty to our customers through a reliable fuel source and direct emissions reductions for their transport operations.

Future Benefits: Deliver enabling infrastructure for future expansion of the Warradarge project to supply mining and mineral processing in the Mid-West region.

Stage 2 Project Objectives

Green Hydrogen Production: Located adjacent to a new wind and solar farm currently under development, Stage 2 will produce hydrogen at a significantly larger scale and lower cost by matching the wind and solar profile.

Feedstock for Industry: Warradarge is working with potential customers in the region to deliver a zero-carbon feedstock for green iron processing, ammonia production and industrial processes.

Stage 1a

Stage 1

Stage 2

Project Specifications

Stage 1a & 1 Project Objectives

Green Hydrogen Production: Utilise renewable energy from a behind the meter connection to Warradarge Wind Farm to produce hydrogen through electrolysis – splitting water sourced and purified onsite from the Yarragadee aquifer. Stage 1a commences with the initial installation of 26MW of electrolysis capacity, scaling up to 196MW to complete Stage 1 and meet customer demand.

Storage & Compression: Hydrogen gas is then compressed and stored onsite ready for transport via tube trailers

Distribution: Efficient and on-time deliveries to our customers at common user refuelling sites along existing high volume transport sites, initially focusing on the Geraldton area.

Economic & Environmental Benefits: Provide tangible financial value and cost certainty to our customers through a reliable fuel source and direct emissions reductions for their transport operations.

Future Benefits: Deliver enabling infrastructure for future expansion of the Warradarge project to supply mining and mineral processing in the Mid-West region.

Stage 2 Project Objectives

Green Hydrogen Production: Located adjacent to a new wind and solar farm currently under development, Stage 2 will produce hydrogen at a significantly larger scale and lower cost by matching the wind and solar profile.

Feedstock for Industry: Warradarge is working with potential customers in the region to deliver a renewable feedstock, including Fenix Resources (ASX: FEX) and VRX Silica (ASX: VRX). Other opportunities are being actively progressed.

Environmental and Community Impact

Environmental Benefits: Reduces reliance on fossil fuels and minimizes greenhouse gas emissions. Local production reducing freight associated emissions.

Community Engagement: Supports local communities by creating employment opportunities and contributing to regional development.

Acknowledgement of Traditional Custodians: Respect for the Traditional Custodians of the land, including their cultural heritage and connection to the area.

Wind Farms

Partnering with existing and planned wind farms to tap into a behind the meter supply of green energy to supply the hydrogen production.

Electrolysis Facilities

A dynamic hydrogen production plant that reacts to the generation available and broader price signals to produce hydrogen from an onsite ground-water source.

Hydrogen Storage and Distribution

A fleet of mobile tube trailers to deliver hydrogen to refuelling stations in strategic locations.